Calculating Minimum Stock Levels For Efficient Inventory

Calculating Minimum Stock Levels For Efficient Inventory

If it’s something you can attach at any time, you can wait to get these expensive items and avoid using your cash or interest on them until you need them. Determine whether extra reporting 529 plan withdrawals on your federal tax return personnel requires a significant reordering level and how quickly production can be ramped up. It is also easier to get a maximum reorder period and stay out of danger levels.

Sections

What are inventory levels?

Ever experienced that sinking feeling when a customer walks away empty-handed because the product they desired is “out of stock”? They can lead to frustrated customers who take their business elsewhere, lost sales, and even damaged reputation. These data are essential in stock management – and also influence the calculation of the minimum stock.

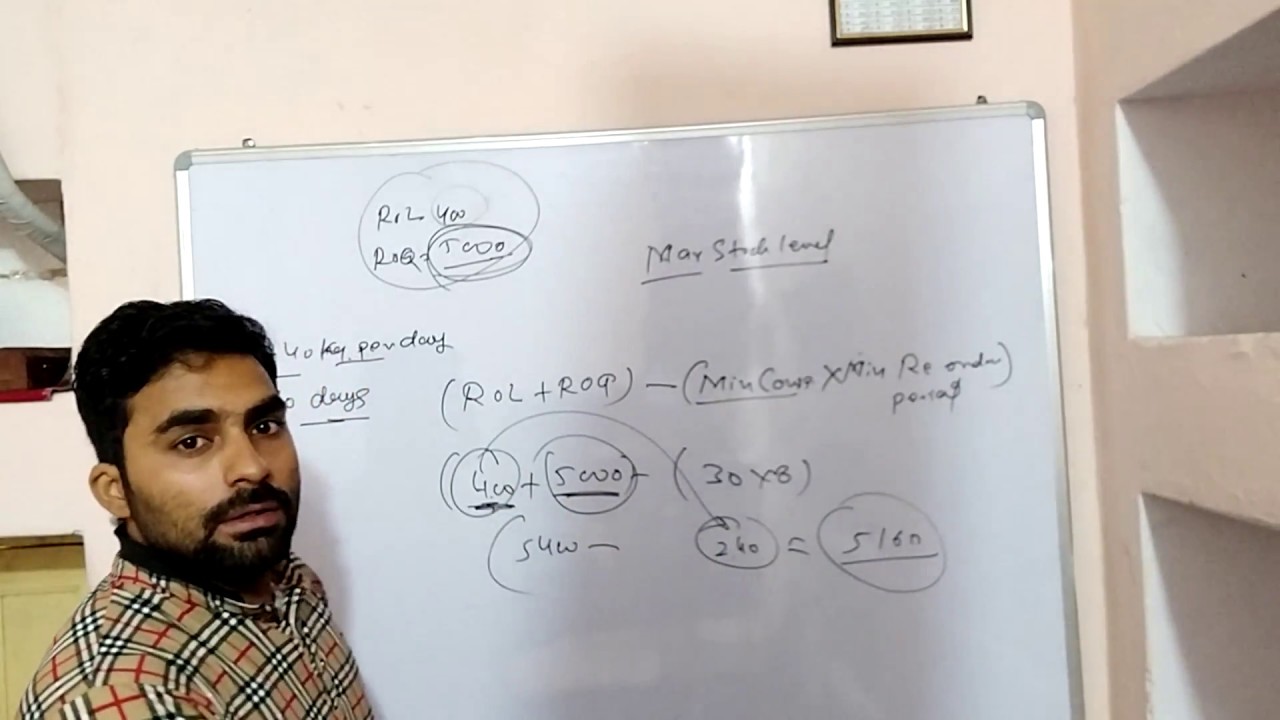

Min/Max Formula for Inventory and Calculation

The optimal order size is that with which the total stock and order costs are the lowest. From a stock perspective, a product should be ordered at the exact moment when the current stock drops below the minimum. (Does this still sound illogical to you? Then read our blog about the optimal order size again). As a result, thanks to the Wilson model, the warehouse manager will know when an order should be placed. Accurate demand forecasting gives businesses a competitive edge, enabling them to meet customer demand without risking stock-outs.

Calculate weeks of supply

In the end, it helps the logistics manager to calculate optimal stock levels and the optimal order volume for each supplier. With efficient inventory forecasting through Fabrikatör, you can consistently keep your inventory between optimal maximum and minimum stock levels. For peak seasons like BFCM and Christmas, forecasting allows you to create a precise inventory plan to maintain balanced stock levels. Fabrikatör also enables you to use data from the same period in previous years, making your stock planning even more accurate. This way, you can manage your eCommerce store effectively without facing overstock or stockouts. Accurately calculating your minimum and maximum inventory levels directly impacts your eCommerce profitability.

For example, an apparel retailer can use these calculations to estimate the right number of winter jackets to stock during the holiday season. This approach helps minimize the risk of running out of popular styles or overstocking less popular ones. By balancing inventory effectively, they can respond to trends and customer preferences, leading to higher profits. We hope this article has given you a better understanding of the min max inventory formula and how you can use it to effectively manage your inventory.

- By calculating and optimizing their minimum and maximum levels, they can prevent such issues, ensuring they have enough stock on hand without overcommitting to excessive storage.

- Knowing how to calculate your value is of paramount importance in managing any business.

- This term may also be known by other names, such as safety, reserve, or protection stock.

- Using technology is an excellent way to have a more reliable inventory.

- Trying to adjust it to an increasingly complex reality lies in integrating specialized logistics management software and basing decisions on measurable data.

Warehouse solutions

PainReform is a clinical-stage specialty pharmaceutical company focused on the reformulation of established therapeutics. PRF-110, the Company’s lead product, is based on the local anesthetic ropivacaine, targeting the postoperative pain relief market. PRF-110 is an oil-based, viscous, clear solution that is deposited directly into the surgical wound bed prior to closure to provide localized and extended postoperative analgesia. The brand typically reorders 1,200 dresses every time they place an order with their manufacturer. Historical data indicates that on slower sales days, especially during off-peak seasons, they only sell around 100 dresses. At Mecalux, we offer Easy WMS, a WMS with multiple applications in the logistics sector.

Depending on the type of business you operate, there are two different strategies from which you can choose. Choose a small order period and replenish your products to the maximum stock at that moment. Then your order period depends on how quickly you sell the contents of a container (or truck). At the time of ordering, replenish your stock of products to the maximum level whenever possible.

Artificial Intelligence (AI) uses advanced analytics and learning algorithms to automate and improve inventory processes. AI can analyze vast volumes of data, translating historical and external demand variables into actionable forecasts. Machine learning ensures that forecasts become increasingly more responsive and accurate. Businesses that monitor inventory in real time and use advanced analytics can respond quickly to these challenges. Those that do, have a competitive advantage over businesses without the same capabilities. Most retail brands rely on spreadsheets to forecast sales and determine optimal inventory.